Well, with the Easter hols here I thought it had been some time since I'd been down to Suffolk to see the Commer so, worrying that it was feeling neglected, I tootled down there for a few days.

Some work has been done on it in my absence, notably fitting the the refurbished carburettor:

The first bit of work was to remove the fuel tank - it's in pretty good condition but I think for longevity it needs protecting so now it's been cleaned, it's off for sand blasting and repainting:

Then the serious work started - setting the timing up and getting it running. This involved much scrabbling around following the workshop manual, as this process involves removing the bell housing cover underneath (harder than it looks as it's hard to get at, sits just above a chassis cross-member and doesn't have captive nuts) then inserting a peg into the front of the flywheel before turning the engine on the starting handle until it locks into position. A quick check to see that this is the right point with cylinder 1 valves closed- yes - then to advance it by 4 degrees, using a screwdriver.

With that done, we gave it a spin and it ran reasonably well for a bit then conked out. Despite great effort it wouldn't re-start so we left that for another time. However, we took the decision there and then to a) convert it to negative earth from positive and b) then to fit electronic ignition with a new coil. Hopefully that might help!

Day two saw mainly a day of electrics. First in line was fitting a new front nearside indicator. With that done, none worked but on removing the switch we found out why - the contacts were all furred up! So off with that, then it was taken apart and cleaned before being refitted and hey presto - they all worked!

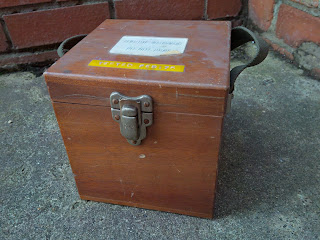

The isolator switch was also finished off:

Then I replaced some of the EFS era dash switches which had seized up - we discovered later that these were for the fog lights and reverse lights, fitted in the early 1980s by the Home Office.

At this stage a little wiggling got the windscreen wipers working again after many years (decades?!) of slumber! Also a little tidying of the cab and under seat storage areas was in order, as well as clearing out the junk. The headlights were also made to work although this required new junctions at the front for both lights as well as rebuilding the switch to make the contacts work properly.

Our attention then turned to the roof, both inside and out - the interior light and the flashing amber lights on the roof. This needed the cab head lining to be removed, no easy task as they are tight fitting and quite brittle! This of course exposed the original cab primer colour, hidden for 60 years:

With that removed, the new correct pattern interior light I obtained from a fellow Q4 enthusiast in Scotland was fitted:

With the headlining out, we discovered the end of the wires for the old 1950s emergency flashing amber beacons on the roof. These must have been isolated at around the same time the Home Office rewire took place but whilst the lights were left, the wire was just cut above the lining. With new wires in place, where was the switch? No idea but with a blanking plate over a hole in the dashboard below the panel lights, that seemed the obvious place for a new switch!

With that all wired in - did the flashing ambers work after well over 30 years of not being used? You bet....

So, back on with the headlining after wiring the interior light back in. Did that work too? Yup....

And that was pretty much it really! Nice to have most of the electrics working again, more progress. Now just to get it running!